UP TO THE MINUTE

Rethinking retrofits: What works and what fails

May 30, 2025 at 6:00 a.m.By Jesse Sanchez.

Explore the reasons why some retrofitting systems are failing and how one company says it's getting it right.

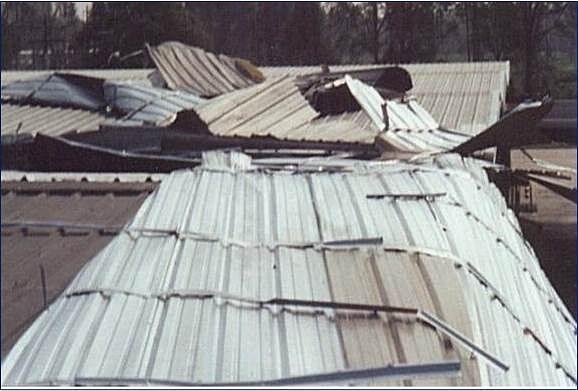

While retrofitting aging metal roofs is standard practice, many widely used methods fall short of structural standards, exposing buildings to serious risks during extreme weather. Roof Hugger, a manufacturer specializing in retrofit sub-framing systems, warns that these shortcomings can lead to costly failures if not addressed properly.

Hat sections, wood purlins, stand-off clips and sprayed-on coatings are among the common methods that raise red flags. The central issue is structural integrity — specifically, the ability to resist wind uplift. Without it, roofs are vulnerable to failure under hurricane-force conditions.

“Many methods being used for retrofitting cannot be considered structurally correct sub-framing systems,” says Roof Hugger. That warning represents a critical gap between appearance and actual performance. Some systems may seem sound but can't deliver the strength required by modern codes.

One example: hat sections installed over existing metal ribs typically allow only a single screw to reach the underlying purlin. The second screw ends up embedded in a thin 26ga. metal panel — a weak point that was never intended to be used for structural attachment and will lead to eventual system failure. Wood purlins, while sometimes used as an alternative, offer poor pull-out strength, the chemicals used in pressure-treated wood also attacks the metal panels that will be attached to them.

Roof Hugger positions its system as a structurally sound alternative. Made from G-90 Galvanized, 16-gauge, grade 55 steel, its components are factory-punched and designed to nest into existing panels while anchoring directly to the original purlins. The system has been installed on more than 120 million square feet of metal roofs, withstanding major hurricanes like Katrina and Ike without a single reported failure.

In a market where shortcuts can mean costly consequences, this approach demonstrates long-term durability and code compliance. The takeaway is clear: not all retrofits are created equal — and the wrong one could lead to more than just leaks.

Learn more about Roof Hugger in their Coffee Shop Directory or visit www.roofhugger.com.

About Jesse

Jesse is a writer for The Coffee Shops. When he is not writing and learning about the roofing industry, he can be found powerlifting, playing saxophone or reading a good book.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In