UP TO THE MINUTE

Building code-compliant roofs that last

July 11, 2025 at 6:00 a.m.By Dale Nelson, Roof Hugger.

Approvals open the door; smart design choices seal the deal.

Florida’s Product Approval, or NOA number, is more than just a formality; it’s your entry point to building strong, code-compliant roofs in one of the toughest wind zones in the country. But here’s the opportunity: understanding what that number really means empowers contractors, designers and building officials to make better, safer choices. Here at Roof Hugger we know that code compliance isn’t automatic; it’s achieved. And when you match the right roofing product to the right design pressures, you’re not just following the rule; you’re building smarter, stronger and with purpose.

In new construction where full sealed plans are required but frequently when re-roofing, a contractor will simply present an FL/NOA # their local building department, they verify the number is valid and voilà’, in a few minutes, they have a permit. There is just one thing – having an FL # or NOA #, it does not automatically mean that that product meets the Florida Building Code (FBC) or the High Velocity Hurricane Zone (HVHZ) code!

What? That can’t be right! Sorry to say it, but that is correct! Florida Product Approvals/NOAs, only provide the “limits of use,” defining maximum wind uplift capacity for each product, installed in a particular way, on a particular roof substrate, based on each particular products testing.

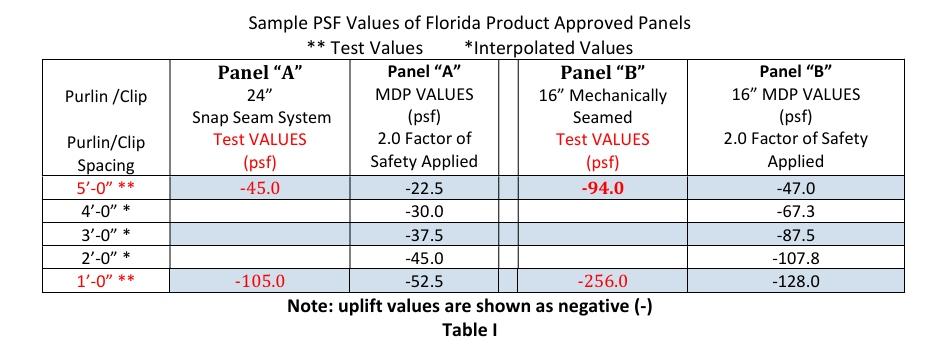

There are several test protocols; each roofing material has its’ own particular test protocol; for structural and non-structural metal roof panel systems, the most commonly accepted industry tests are UL-580, FM 4471 and E-1592. Each test can take a panel to its ultimate failure point. Failure is typically fastener pull out, seam/joint disengagement, deflection or roof clip failure. Once the point of failure or ultimate capacity is established a factor of safety is applied to it (typically 2.0) and that becomes the “Maximum Design Pressure” (MDP) you can use in design calculations. If a panel system’s last sustained pressure before failure was -120 psf you can use an MDP of -60 psf (-120/2= -60) as your roofing materials maximum useable capacity.

Well ok, that’s getting a bit technical but if the product has a FL # and it is also UL-90 rated, then at least it is good for -90 psf wind uplift – right? Wrong again. UL-580 tests are pass/fail tests that place a cycling pressure on a given roof product assembly and for a specific period of time. To be UL-90 rated a panel must sustain -105 psf for a specific period of time and if it does, it passes and can be UL-90 rated. Once again, Florida requires a minimum “Factor of Safety” of 2.0 therefore a UL-90 rated product will typically have a MDP limit of -52.5 psf (-105/2= -52.5 psf).

So, what does this all mean for designing and permitting a new roof or a re-roofing project? This part is pretty straight forward: The tested capacity of the roofing material, must exceed the ASCE 7-22 required design uplift loads or the product will not meet code requirements for FBC or HVHZ.

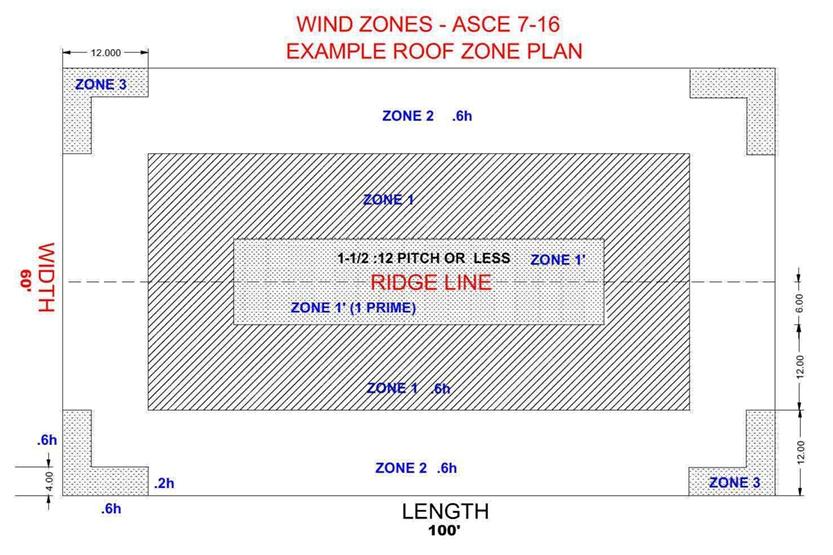

So how do we know what the design uplift loads are? It all starts with the American Society of Civil Engineering’s ASCE-7 published design criteria. Florida has adopted ASCE 7-22 as its current criteria, it establishes the size and shape of roof zones and the minimum uplift pressure each zone must be resist. On a simple low slope, gable building, there are 4 primary roof zones (plus 3 roof overhang zones): The Corners (Zone 3) are where the loads are typically highest, The Perimeter or Edges (Zone 2) are where the loads are higher but less than the corners and The Field (Zones 1 and 1’) are where the loads are the lowest.

A typical low slope roof plan would look like this:

For example: The ASCE-22 loads for a General Occupancy, 60’ wide x100’ long x20’ high, 1:12 pitch, Enclosed, pre-engineered building with 5’ purlin spacing located in Clearwater, Florida with a 145-mph wind speed, Exposure “C” are approximately:

Minimum ASCE 7-22 loads by roof zone:

Note: uplift values are shown as negative (-) numbers

- Zone 1: -46.6 psf

- Zone 1’: -26.8 psf

- Zone 2: -61.4 psf

- Zone 3: -83.7 psf

Let’s look at this building comparing two sample* Florida Product Approved Metal Roof Panel Systems:

Example only – not actual panel system.

Panel System A

Panel System “A” is a new 24” Trapezoidal Standing Seam with snap-together seams:

- Maximum Design Pressure -22.5 psf when attached to purlins 5’-0” o.c.

- Maximum Design Pressure -52.5 psf when attached to purlins 1’-0” o.c.

- Test Values between 1’-0” and 5’-0” can be interpolated per Table I.

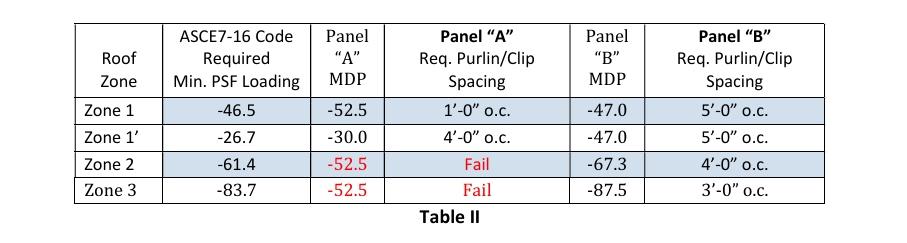

- Roof panel “A” can meet the -46.5 psf Zone 1 loads on 1’-0” clip/purlin spacing.

- Roof panel “A” can meet the -26.7 psf Zone 1’ loads on 4’-0” clip/purlin spacing

- Roof panel “A” FAILS TO MEET -61.4 psf Zone 2 loads on any clip/purlin spacing.

- Roof panel “A” FAILS TO MEET -83.7 psf Zone 3 loads on any clip/purlin spacing.

This panel cannot be used even though it is Florida Product Approved. See Table II

Panel system B

Panel System “B” is a new 16” Mechanically Seamed Standing Seam:

- Maximum Design Pressure -47.0 psf when attached to purlins 5’-0” o.c.

- Maximum Design Pressure -128.0 psf when attached to purlins 1’-0” o.c.

- Roof panel “B” can meet the -46.5 psf Zone 1 loads on 5’-0” clip/purlin spacing.

- Roof panel “B” can meet the -26.7 psf Zone 1’ loads on 5’-0” clip/purlin spacing

- Roof panel “B” can meet the -61.4 psf Zone 2 loads on 4’-0” clip/purlin spacing.

- Roof panel “B” can meet the -83.7 psf Zone 3 loads on 3’-0” clip/purlin spacing.

If this was an existing metal building and the purlin spacing was 5’-0”, Zones 2 & 3 will need additional framing to reduce the existing spacing. This can be accomplished in an existing building by inserting new purlins under the old roof or with additional framing on top of the existing roof. New construction projects will have purlins spaced to meet the panels attachment requirements.

This example is for an industrial open purlin pre-engineered building but the same procedure applies to residential metal roofing except the FPA would typically be for “Metal Panels Attached to Plywood” or for “Metal Panels Attached to Structural Decking. The table and values will be different but the principal is the same, the roofing material capacity, at a given attachment spacing, must exceed the code required loads in each of the roof zones.

The important point here is that although both roof panels in these examples have Florida Product Approval, only one meets the FBC Requirements for use on this project.

All roofing materials, Conventional and Metal, have similar limitations on their use. Simply selecting a product that is “Approved” does not mean it is appropriate or will meet the code required loadings. The test values must be compared to required loads.

Recommendations

When selecting a material for a new or re-roofing project:

1 – Find out what the ASCE-22 required roof loads are in each zone as well as the zone size and shape. Different roof pitches and shapes will have different zone configurations. Many panel and retrofit framing system suppliers will assist you with an estimate of these loads, but consulting a professional engineer is the safest and easiest way to assure compliance.

2 – Understand the ‘Limits of Use” for the roofing product you want to install. Make sure it exceeds the code minimums. Remember each product, although similar to one another, will have its own specific limits.

3 – Make sure your building framing is within the parameters of the Product Approval. If the building is outside those parameters, consult a professional engineer to determine how to proceed.

4 – Finally, when installing the Product, make sure you install it exactly as stated in the Engineered and Product Approval Documents and Drawings. Do not substitute fasteners, clips or change the panel gauge with components other than what has been certified. Failure to follow the installation guidelines may result in a non-code compliant assembly.

Florida’s Building Codes and the related Product Approvals have set a high bar to insure strong, durable, high-quality roofs, understanding and following the details and limitations of the selected Approved Product is key to long-lasting roof and maintaining full code compliance.

Original article and photo source: Roof Hugger

Learn more about Roof Hugger in their Coffee Shop Directory or visit www.roofhugger.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In