UP TO THE MINUTE

Military Snaps to Attention

By Robert Scichili and Scott Kri, Retrofit Magazine.

The U.S. Department of Defense tests metal roof technology integrating renewable energy and sustainability features.

According to Washington, D.C.-based Energy Star, there are 4.8 million existing commercial buildings in the U.S. and 40 percent of them were built prior to 1970, a time when energy efficiency was not the priority it is today. As a result, our nation has a large inventory of buildings that are poorly insulated and are using inefficient appliances, air-handling equipment, lighting and windows.

The good news is work has already begun on the use of new building technologies and systems to implement energy-efficient solutions to these buildings. In fact, a number of federal agencies and departments have stepped up their activities to set an example toward meeting new efficiency goals. Consider the following:

- Executive Order 13514 was signed by President Barack Obama in 2009 to seek lower greenhouse-gas emissions in federal buildings 28 percent by 2020.

- The U.S. General Services Administration has established its high-performance building department to ensure all retrofit buildings feature sustainable design characteristics, including those that improve energy efficiency, optimize the use of potable water, manage stormwater runoff, and improve the interior comfort and air quality of the 500,000 buildings GSA oversees.

- The U.S. Department of Energy remains focused on research into more energyefficient building products, technologies and systems, including retrofit applications. DOE’s Office of Energy Efficiency and Renewable Energy provides millions of dollars to improve materials, manufacturing processes and supply chains for photovoltaic systems used in retrofit applications.

Even the U.S. Department of Defense, which is the world’s largest consumer of energy, is taking a leadership role in energy, sustainability and retrofit solutions for the 2.4 billion square feet of building space it operates. By installing a test retrofit project at Goodfellow Air Force Base, San Angelo, Texas, DoD is learning how today’s roofing technologies can enhance its energy-efficiency goals.

The mandates

In 2007, Congress passed the National Defense Authorization Act, which requires DoD to produce or procure 25 percent of all energy from renewable sources by 2025. In addition, the federal government has mandated DoD institute a 30 percent energy use reduction on its properties by 2015 and another 37.5 percent reduction by 2020.

Through the use of the DoD Environmental Security Technologies Certification Program (ESTCP), the military is providing grants to industry to demonstrate commercially available and sustainable novel technologies, products and systems aimed at meeting DoD’s energy- and water-conservation goals.

One such ESTCP grant was awarded in 2010 to a team of metal construction industry-leading companies and the Metal Construction Association, Glenview, Illinois. The approximate $1 million grant is being used to demonstrate a retrofit metal roof system with integrated renewable energy technologies that showcases a holistic assembly of six different roofing system components. The ESTCP grant was awarded to this team in particular because the group offered the only retrofit metal roofing system integrating other energy-saving technologies to form a building envelope.

Retrofit team and materials

These core team members have been tireless in their time and talent toward the three-year grant process and attainment of the grant itself. The significance of the ESTCP grant award is there is no metal roof assembly in demonstration anywhere that will have the impact of what has been installed at Goodfellow Air Force Base, San Angelo, Texas.

- Roof Hugger, Odessa, Florida - Mark James, vice president, and Dale Nelson, president, provided expertise in preparing the grant proposal, as well as engineered and manufactured the roof sub-purlins that make the metal-over-metal retrofit envelope possible.

- Paramount Metal Systems, Little Rock, Arkansas - David Dodge, president, and Jeff Slagle, project manager, made the installation of all components a smooth process through excellent cooperation with Air Force base personnel.

- Pfister Energy, Hawthorne, New Jersey - William Poleatewich, director of new technologies, engineered, provided and oversaw the installation of the solar power, solar water and rainwater catchment systems that drive the heart of the energy and water savings.

- Dow Building Solutions, Midland, Michigan - Tom Evans, national business development manager, provided Thermax insulation for above and below roof purlins, as well as provided expertise about thermal issues.

- Metal Construction Association Glenview, Illinois - Scott Kriner, technical director, provided expertise in preparing the grant proposal and in reviewing the testing program to ensure authenticity. Robert Scichili Associates Richardson, Texas Robert Scichili, president, provided expertise in writing the grant proposal and testing to be done. He acts as the principal investigator for the project, the grant team and ESTCP.

The installation

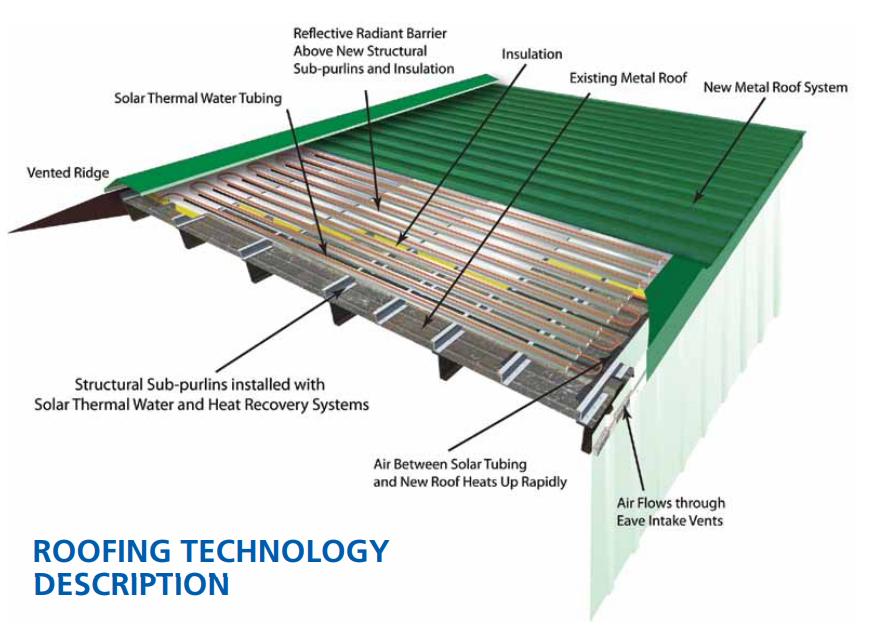

The project targeted retrofitting an 11,900-square-foot metal roof on a 10,000-square-foot Security Forces building at Goodfellow Air Force Base. Prior to the installation of the roof system, DOE’s Oak Ridge National Laboratory, Oak Ridge, Tennesee, installed a data acquisition system to monitor various temperatures and heat information on the building. In addition to measuring energy data, the building’s utility billing information was collected. When the baseline of energy usage was established, installation of the retrofit metal roof system began in April 2012 and was completed in June 2012. The integrated technologies were installed in the following manner:

- Structural purlins were installed over the existing metal roof.

- Additional insulation, using rigid insulation board, was placed over the existing roof to meet the current code requirements.

- A waterproof roof underlayment was then applied over the insulation.

- A radiant barrier was installed over the underlayment.

- An integrated solar thermal system using a closed-loop tubing array with a water/glycol mix heat-exchange medium was installed over the radiant barrier to optimize the heat transfer.

- The thermal purlin used to position the solar thermal system tubing is configured to allow for above sheathing ventilation (convective cooling) to take place from the eave to the ridge.

- Panels of 24-gauge standing-seam metal roofing, prepainted with a polyvinylidene fluoride cool coating, were laminated with a thin-film PV system and then installed directly over the solar thermal system.

The holistic use of these integrated components into one retrofit system is designed to maximize electricity generation and minimize the cooling load of the building. In addition, the solar-thermal technology that is integrated into the retrofit cavity will optimize the energy generated for domestic hot water and space heating.

The project is expected to yield more than 750,000 KBtu of energy per year through savings from energy-efficiency improvements to this building or harvested energy generated from solar-power systems on the roof. With the local utility costs taken into account, Goodfellow Air Force Base is estimating a savings of $11,750 per year on this building thanks to the retrofit roof.

With the retrofitted integrated metal roof system in place, the surface of the roof is now being used to capture rainwater in an above-ground cistern with a 10,000 gallon capacity. It is estimated that a typical 2-inch rainfall in the San Angelo region will generate 6,500 gallons of rainwater being captured from one side of the roof. The rainwater will be used for irrigation purposes on the base. Estimates suggest 131,000 gallons of potable water per year will be saved from being used for irrigation.

The data

With the full installation and commissioning now complete, the plan is to have ORNL continue monitoring data during the next 12 months. Data will be taken on:

- Temperatures

- Heat transfer

- Energy output from the photovoltaics

- Energy consumed by the building

- Water usage

The ESTCP, DoD and project team are confident this integrated retrofit roof system will perform as predicted and allow for the technology to be transferred throughout DoD, as well as to other federal agencies and ultimately into the commercial building sector.

Learn more about Roof Hugger in their directory or visit www.roofhugger.com.

Original article: Retrofit

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In