UP TO THE MINUTE

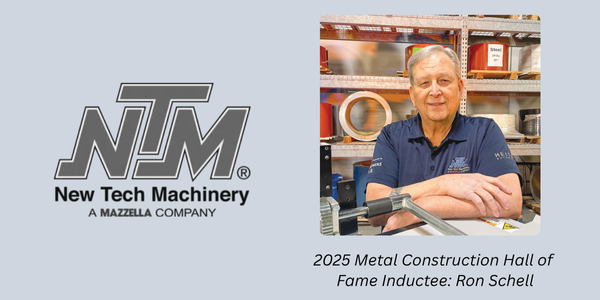

Ron Schell: Transformed the world of metal rollforming through unmatched ingenuity

June 23, 2025 at 6:00 a.m.Ron Schell is not just a name in the metal fabrication industry but synonymous with innovation.

Ron Schell is not just a name in the metal fabrication industry but synonymous with innovation. For 45 years, his relentless pursuit of better solutions has reshaped the rollforming sector, leaving an indelible mark on how buildings are constructed.

This honoree’s story began in 1979 at Watertite Industries. Starting in an entry-level position, his talent quickly became apparent. By 1982, he had risen to plant manager and design engineer, overseeing the production of gutter, downspout, elbow, and flashing machines. It was here that the seeds of his revolutionary ideas were sown. He spearheaded improvements in manufacturing processes and trained distributors on equipment maintenance, demonstrating a dedication to efficiency and knowledge sharing.

However, Schell’s true breakthrough came with the development of the prototype of the Mach II portable seamless gutter machine. This was not merely an improvement; it was a paradigm shift. Traditional gutter machines relied on hard rollers for drive and forming, making them difficult to service and adjust. Schell’s ingenious innovation separated these functions, creating a more efficient and user-friendly machine. It is not hyperbole to say this single innovation revolutionized the industry.

Unfortunately, Watertite Industries ceased operations before the Mach II could be brought to market, and the prototype was sold at auction. Undeterred, Ron and three former Watertite employees established Jobsite. They refined the Watertite machine and continued its production for three years, eventually selling the company name and product line to a manufacturer outside the rollforming sector.

His expertise caught the attention of New Tech Machinery, who brought him on board to finalize the Mach II design and contribute to developing the SSP (later SSQ II) metal roof panel machines. Two years later, in 1994, the first Mach II machine rolled off the production line.

The impact of the Mach II was profound. Schell’s innovations addressed critical challenges in the industry: separate drive and forming rollers boosted machine efficiency; polyurethane-coated drive rollers allowed for compatibility with various metal types without constant adjustments; and the transportable design eliminated the need to preload metal coils, drastically reducing material waste. The Mach II became the industry standard—it is so widely copied that it is a testament to its groundbreaking design. Not content to rest on his laurels, Schell introduced the 127 mm/152 mm (5 in./6 in.) combo gutter machine in 1995, further cementing his influence.

Schell’s ingenuity wasn’t confined to gutter machines. His development of a quick-change profile system for the SSQ II panel machine was another game-changer. Previously, changing profiles required two people and four hours of painstaking work. Schell’s system allowed a single operator to accomplish the same task in 45 minutes with a single wrench. This dramatically increased productivity and reduced downtime.

Holding nine patents with New Tech Machinery, Schell’s contributions are numerous and impactful. Beyond the Mach II and the SSQ II quick-change system, his patents include the BG7 box gutter machine and 5VC-5V Crimp Machine. The New Tech Machinery SSQ II Roof and Wall Panel Machine, a direct result of Schell’s vision, is now a leading portable standing seam roof panel machine globally, frequently featured in trade journals and industry exhibitions.

Even after retiring in 2019, Schell’s passion for engineering and service remains strong. He returned to New Tech Machinery in 2021 to mentor new engineers, service technicians, and machine builders, ensuring his legacy of innovation continues to inspire future generations.

As originally posted in Metal Construction News April 2025.

Learn more about New Tech Machinery in their Coffee Shop Directory or visit www.newtechmachinery.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In