UP TO THE MINUTE

Removing your roof? – You may regret it!

June 6, 2025 at 6:00 a.m.By Roof Hugger.

Upgrading your metal roof could backfire, unless you know this first.

It sounds simple enough: swap out that tired old screw-down roof for a sleek, modern standing seam upgrade. But one wrong move, such as removing what’s literally holding your building together, could cost you far more than you bargained for. As the push for energy efficiency and longevity drives building owners to retrofit their aging metal roofs, many are overlooking a hidden structural role their current roof quietly plays. According to Roof Hugger, tearing it off without a plan could mean compromising your building’s backbone.

The screw-down metal roof and wall panel has been the backbone of the metal building industry since its inception many decades ago and still represents a significant part of the total market. Screw-down panels are lightweight, durable, inexpensive and strong enough to span up to 5’ between structural supports. Screw-down roofs and walls also have a wonderful physical property. The panels can and frequently are used as “diaphragm bracing,” securely holding the building’s roof purlins and wall girts in position, adding rigidity to the structure in much the same way drywall strengthens the stud walls it is fastened to. This is a huge material and labor cost saver! The structural purlins are held in position by the panels.

The early systems were not without problems however; much of the technology we take for granted today did not exist in the early years of pre-engineered buildings. Many roofs installed during the late 1960s through the early 80’s were done so using 10-year life fasteners to secure a 30+ year life roof.

The fastener issue seems crazy today given the numerous inexpensive, long-life, weather tight, self-drilling screws available but back when I started in the metal building industry you could have the newly developed “self-drilling” cadmium fasteners or “self-tapping” stainless. Self-tapping meaning you had to pre-drill a hole in the panel and purlin to install it, a much slower and more expensive process. Most of us used the less expensive but (unknown to us at the time) fairly short life cadmium coated fasteners, often never providing the option of a stainless upgrade to our customers.

Another short coming with screw-down roof panels is that, generally speaking, screw-down panels on metal buildings should be a maximum length of about 80’. Longer roof panel runs frequently suffered rips or slots in the metal caused by expansion and contraction. Metal panels expand and contract at a rate of about 1”/ 100’ of panel run. This is normally absorbed by the back and forth rolling of the roof purlin and some panel bowing but after 80’ or so they can no longer absorb the movement resulting in trauma to the panels and trim.

Standing seam panels eliminate both of these shortcomings. The panels are attached with “sliding clips” not screws to the structural purlins. The clips are screwed to the purlins and seamed into the side laps of the panels securing them and thus the panels have very few, if any, exposed fasteners. The clips maintain a solid connection with the structure of the building while still allowing the panels to move with expansion and contraction forces without damage.

This is great news for the building owner providing a more watertight roof, few if any penetrations and expansion and contraction ability. This does come with a catch however; standing seam panels, because they move, do not provide diaphragm strength. The buildings’ roof purlins must have significantly more bridging and bracing to keep them in their correct and upright position. This is automatically taken care of in new building design but when it comes time to reroof an older building, removing the existing screw-down roof could remove the diaphragm bracing it once provided and make the building structurally unsound – yes, that’s bad!

So how can you upgrade to standing seam roofing?

- Removing your old roof can be still done but a structural engineer must be hired to design the bracing needed to properly support the existing purlins for the new standing seam roof. Properly positioned angle bracing, band strapping or support channels will likely be required. I have heard several horror stories of buildings that shook and rattled in the slightest breeze where an old screw-down roof was removed, and a standing seam was installed without re-bracing the purlins.

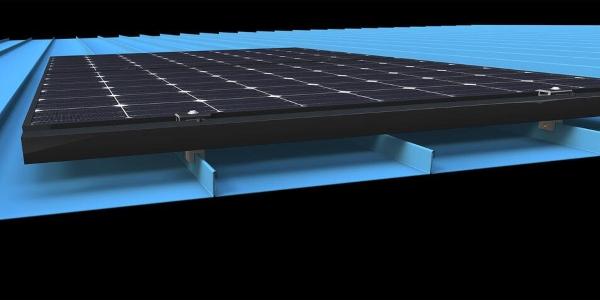

- Leave the existing roof in place and retrofit on top of the existing roof. This is the easiest and least expensive option and can be accomplished with any one of the following systems:

- Notched sub-purlin systems: Low profile, framing systems that are cut out to fit over the ribs of the existing panels. Systems can be designed to strengthen the existing purlins to handle the weight of the new roof system. They can also be ordered in custom heights to provide additional insulation between the old and new roofs. This system is also easily modified to add additional panel support to meet the newer building codes.

Learn more about Roof Hugger in their Coffee Shop Directory or visit www.roofhugger.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In