UP TO THE MINUTE

Stronger seals for smarter metal installs

June 25, 2025 at 3:00 p.m.By Gaco.

Why the right sealant makes the difference in long-term performance and weatherproofing in metal buildings.

In the construction of modern metal buildings, long-term performance hinges on more than just the structural design — it depends on what seals everything together. While often overlooked, non-skinning sealant plays a critical role in maintaining weather-tightness, energy efficiency and durability, particularly in Insulated Metal Panels (IMPs) and Standing Seam Roof (SSR) systems.

Key challenges in metal building construction

Metal buildings are designed for strength, efficiency and longevity, however achieving those outcomes requires more than precise installation — it demands the right sealing solutions to combat:

- Thermal movement, which causes panels to expand and contract

- Moisture infiltration through laps, joints and penetrations

- Air leakage, reducing insulation effectiveness and increasing energy costs

- Exposure to harsh environments, including UV, wind and temperature swings

These challenges make the selection of high-performance sealants critical to ensure a weather-tight building envelope and protect structural integrity over the building’s lifespan.

The role of sealants in metal install applications

Sealants are widely trusted in metal building systems for their strong adhesion, long-term flexibility and resistance to the elements. Unlike traditional caulks or hardening sealants, butyl based sealants and non-skinning sealants maintain performance without cracking or drying out over time. They provide a consistent, long-lasting barrier against moisture and air infiltration — critical in both factory-assembled and field-installed systems.

What happens when you don't use the right sealant?

Using the wrong sealant — or skipping sealant altogether — can lead to:

- Water penetration and corrosion

- Loss of thermal performance

- Premature material degradation

- Increased maintenance and repair costs

- Voided warranties and failed inspections

Types of sealants and their application areas

Metal building sealants generally fall into two categories: butyl tape sealants and non-skinning sealants, each suited to specific needs in metal construction.

Butyl tape or non-skinning sealants: What’s the difference?

|

Feature |

Butyl tape sealants |

Non-skinning sealants |

|

Application areas |

Rib joints, end laps, roof curbs, skylights |

Panel joints, concealed seams, roll-forming joints |

|

Form |

Pre-formed tape rolls |

Fluid sealant (packaging options: caulk tube, sausage pack, pail or drum) |

|

Installation |

Peel-and-stick; tool-free |

Requires gunning or pumping |

|

Movement Tolerance |

Moderate – conforms to surface |

High – ideal for dynamic joints |

|

Repositioning ability |

Limited after initial application |

Easily repositionable during install |

|

Mess/cleanup |

Clean; minimal residue |

Clean application; no stringing or webbing |

|

Priming required |

No priming required |

No priming required |

|

Best for |

Simple joints, exterior sealing, easy installs |

High-movement areas, factory/field panel joints |

|

Flexibility |

Maintains shape; flexible |

Non-hardening and fully flexible over time |

|

Appearance |

Hidden between joined surfaces |

Hidden within seams or panels |

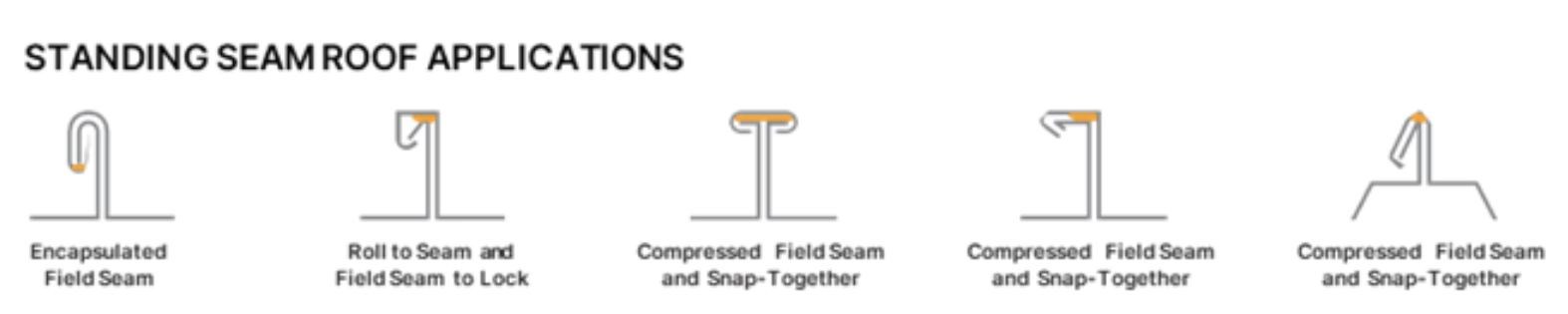

Butyl tape sealants are ideal for sealing metal rib and end joints, standing seam roof end laps and around roof curbs, jacks and skylights. They’re highly tacky, adhere to common metal coatings like Kynar®, Galvalume® and Zincalume® and apply easily without tools — even in temperatures from -5°F to 120°F. Permanently flexible and UV/weather-resistant, butyl tapes won’t crack or flow under stress. With an 18-month shelf life and a variety of sizes, they’re a proven, reliable choice across metal building types.

Non-skinning sealants are designed for more dynamic applications, such as IMP joints, standing seam concealed seams and roll-forming lines. Their non-hardening formula stays flexible over time and allows repositioning during install. Easy to apply with no priming or cleanup required, they bond well to clean surfaces and adapt to joint movement from thermal expansion. Available in tubes, pails or drums, they offer clean, efficient sealing for both factory and field use.

GacoSeal™ Solutions for metal building construction

GacoSeal™ SM5430 Non-Skinning Sealant is specifically formulated for both factory and on-site use in insulated metal panels (IMPs) and standing seam roofing applications. It offers excellent pumpability, works without the need for priming and provides over 50 linear feet of coverage per tube with a typical 3/16" bead — making it a go-to for installers looking for consistent, long-term performance without the cleanup headaches often associated with other sealants.

GacoSeal™ SM5227 Butyl Tape Sealant complements this with a high-tack, easy-to-apply solution perfect for end laps, rib joints, skylights and roof curbs. It adheres well to a range of coated metal substrates and is designed to remain flexible and durable through harsh conditions.

With proven in-field performance, GacoSeal solutions are designed to support metal building longevity and installer confidence from start to finish.

Conclusion

Choosing the right sealant is essential for protecting your metal building from the start. With proven performance, flexibility and weather resistance, butyl based sealants — both tape and non-skinning varieties — are critical tools in the contractor’s arsenal. Whether you’re sealing a cold storage facility or installing a standing seam roof, using the correct product ensures fewer callbacks, lower lifecycle costs and higher customer satisfaction.

Learn more about Gaco in their Coffee Shop Directory or visit www.gaco.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In