UP TO THE MINUTE

Store Your Metal Roofing Panels and Trim Like a Professional

By Cass Jacoby.

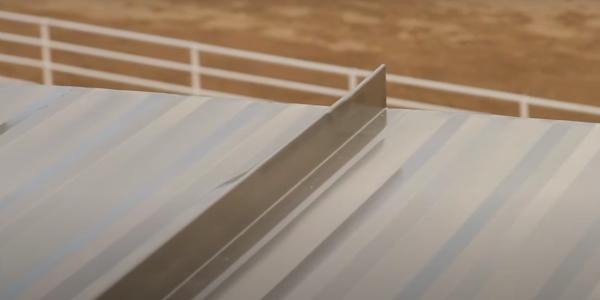

By learning the best methods to properly handle your roofing panels you maintain the integrity of the roofing system.

If you are a metal roof installer, the chances are at one point you will need to move and handle the panels or even store them. While it might sound like an easy task, it is deceptively complex, as there are definite rights and wrongs to storing your metal panels that can affect safety, profitability and product integrity.

Sheffield Metals International is a leading supplier of metal sheet and coil products for the standing seam metal roofing industry. Their in-house Technical Department works with contractors and manufacturers alike to ensure that metal panels are properly handled, stored and installed. They know that it is important to a contractor for a project to be successful, so proper storing and handling is paramount.

The stakes of mishandling metal roofing panels and trim

You may think to yourself that improper handling of a panel doesn’t seem like such a big deal, however, there are at least several ways that careless handling can damage a panel including:

-

Kinks, dents or unsightly bends in the panels – Moving panels too roughly or without proper support can dent and bend the panels or even warp them enough to make them unusable in the installation.

-

Increases the likelihood of oil canning – Oil canning is a visual phenomenon that makes metal panels look wavy or somewhat distorted. Improper moving, twisting and handling of panels can allow for opportunities for this effect to happen.

-

Scratches or gouges that go down to the metal core – If a panel is dropped it can cause damage severe enough to gouge through the paint or coating system and reach the metal core. This can void the paint/substrate warranty before it even gets on the roof. Metal panel coatings are very thin (around 1 mil or 0.0254 mm), so dropping a panel can do some serious damage.

Essentially, mishandling a panel can cause irreversible damage that can seriously affect your work as a contractor. Thus, proper handling of a panel is essential.

Tips for how to handle metal roofing panels

While there is no set way for carrying every single metal roofing panel, there are best practices worth following.

1 - The number of people required to move and handle a panel directly relates to the length. You essentially should have:

-

Under 6 feet: one handler

-

Between 7 and 15 feet: two to three handlers

-

Between 16 and 30 feet: three to four handlers

-

Between 31 and 45 feet: four to five handlers

-

Over 45 feet: four or more handlers (while practicing extreme caution not to let the panel sag, bend, kink or drop)

2 - If more than one handler is recommended, each handler should be 10 to 12 feet apart, and the first and last handlers should be approximately 5 feet from the ends.

3- If the panel should be carried on its side, the flat part of the panel should be perpendicular to the ground.

Carrying panels on the side creates more rigidity and makes them less likely to bend, especially in the flat area. Make sure to support the bottom of the panel and not carry it from its seams.

4 - It’s best to wear cut-resistant gloves.

Rollformed panels are often sharp or pointy, so protect your hands with cut-resistant gloves. Wearing gloves additionally keeps the natural oils on your skin from staining zinc and copper panels.

5 - Panels should be moved one at a time.

6 - Place the panels on a supporting surface with care.

You should not lay panels directly on the ground, as this opens up the panel for opportunities to get damaged. Instead, support the whole panel length so that the panels are not touching the ground.

7 - Always take the PVC film off the panels after rollforming, but before panels are installed.

Keeping the PVC film on while handling panels can provide an extra protection layer. However, do not forget to remove it before the installation. PVC film should always be taken off before any level of exposure to UV, extreme heat or moisture as this can break the PVC down, making it difficult to remove and/or leaving adhesive residue on the painted metal surface.

8 - To get the panels up to the roof deck, you can:

-

Hand them up individually using the perpendicular panel handling method

-

Use a forklift or crane

-

Lift the rollformer up to the roof height and rollform the panels directly onto the roof deck

Read more on how to properly handle and store metal panels on Sheffield Metals’ website.

Learn more about Sheffield Metals in their directory or visit SheffieldMetals.com.

Comments

Leave a Reply

Have an account? Login to leave a comment!

Sign In